Welcome to the "Insight into Our Production Processes and Flow" section of the BPPL website, where we invite you behind the scenes to discover the intricacies of our manufacturing operations. At BPPL, we take great pride in our commitment to excellence and innovation, and nowhere is this more evident than in our production processes. Here, we provide a comprehensive overview of how we transform raw materials into high-quality copper and aluminium products that meet the exacting standards of our customers. Join us as we delve into the heart of our operations and gain valuable insights into the meticulous planning, cutting-edge technology, and unwavering dedication that drive our success.

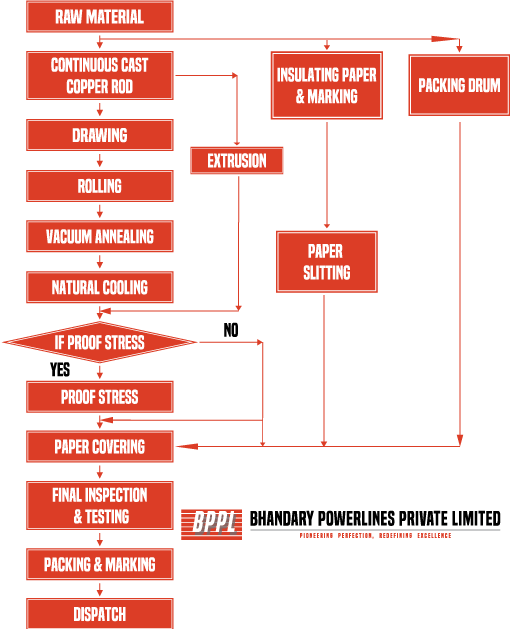

At BPPL, our production process is meticulously designed to ensure efficiency, quality, and reliability at every stage. Our generic production flow chart provides a visual representation of our streamlined manufacturing process:

Initiation

The production process begins with the initiation phase, where raw materials are sourced and inspected for quality and suitability. Once approved, the materials are ready for processing.

Processing

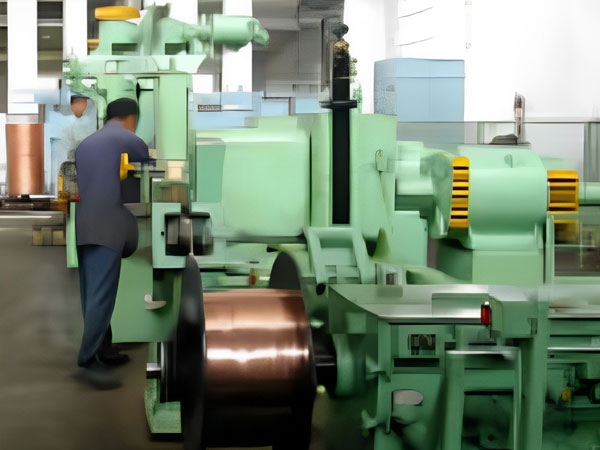

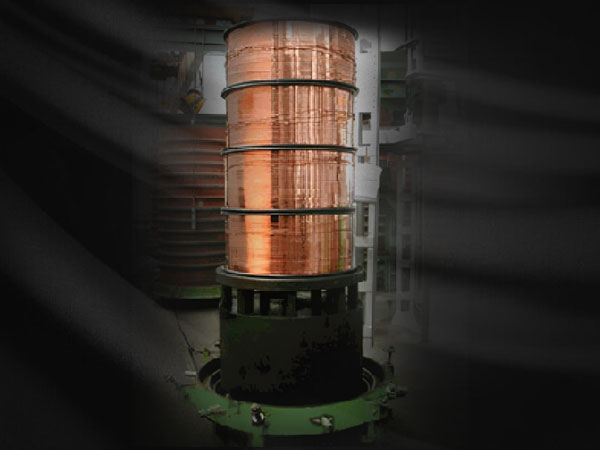

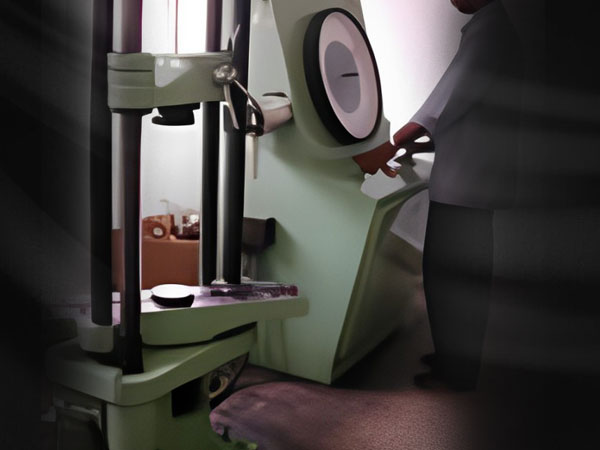

During the processing phase, the raw materials are transformed into finished products through a series of precision manufacturing techniques. This may involve extrusion, drawing, rolling or other specialized processes, depending on the product requirements.

Quality Control

Quality control is an integral part of our production process. At BPPL, we adhere to strict quality standards to ensure that every product meets our rigorous specifications. Throughout the manufacturing process, our dedicated quality control team conducts thorough inspections and tests to verify compliance with industry standards.

Final Inspection

Once the products are manufactured, they undergo a final inspection to ensure that they meet all quality requirements. Any deviations or defects are identified and addressed before the products are approved for shipment.

Packaging

After passing the final inspection, the products are carefully packaged using specialized packing materials to ensure safe transportation and delivery to our customers. Our packaging process is designed to protect the products from damage and environmental factors during transit.

Shipping

The packaged products are then prepared for shipping, with careful consideration given to logistics and delivery schedules. At BPPL, we prioritize timely delivery and strive to ensure that our products reach our customers in pristine condition, and ready for use.

Generic Production Flow Chart

Our Advanced Manufacturing Process

Ensuring Quality at Every Step

Raw Material

Drawing

Rolling

Annealing

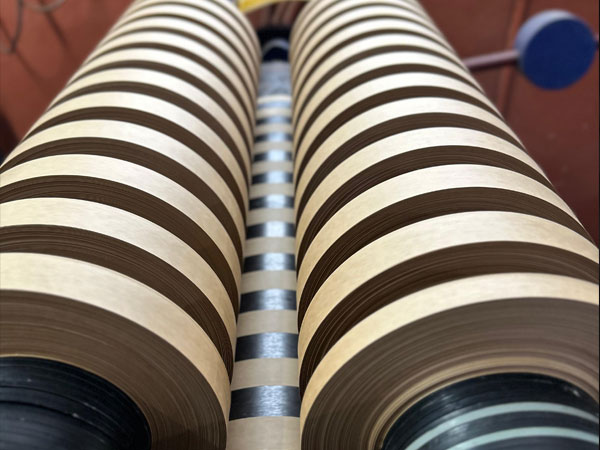

Paper Slitting

Paper Covering

Testing

Packaging

By following this comprehensive production flow chart, BPPL maintains the highest standards of quality, efficiency, and customer satisfaction throughout the manufacturing process.

EOHS and IMS Policies of BPPL

EOHS POLICY

We BHANDARY POWERLINES PVT LTD are committed to implementing Integrated Management Systems (IMS) to achieve continual improvement in our overall Environment and OH&S performance through consistent monitoring.

We will achieve our Goals through:

- Proactive implementation of environmentally sustainable and safe practices which result in quality deliverables.

- Protection of the environment, including prevention of pollution and any other specific environmental matters relevant to the organization.

- Compliance with all applicable requirements and compliance obligations.

- Participation and consultation with Workers and worker representatives in matters of Environment, Health, and Safety.

- Prevention of injury and ill health by eliminating OH&S Hazards and associated risks.

IMS POLICY

We BHANDARY POWERLINES PVT LTD are committed to implementing Integrated Management Systems (IMS) to achieve continual improvement in our overall Environment and OH&S performance through consistent monitoring.

We will achieve our Goals through:

- Proactive implementation of environmentally sustainable and safe practices which result in quality deliverables.

- Protection of the environment, including prevention of pollution and any other specific environmental matters relevant to the organization.

- Compliance with all applicable requirements and compliance obligations.

- Constant engagement with stakeholders facilitates participation and consultation in matters of Environment, Health, and Safety.

- Prevention of injury and ill health by eliminating OH&S Hazards and associated risks.

- Involving workers and worker representatives in all the day-to-day activities to improve the performance of the organization.

By following this Standard Operating Procedure, BPPL ensures an accurate and reliable determination of the resistivity of Copper, thereby maintaining the highest standards of quality and performance in our products.

Products- Applications:

At BPPL, our products find applications across the worldwide, catering to the unique needs and requirements. With our portfolio of high-quality copper and aluminium products, we serve as a trusted partner to Power Generation and Distribution sector. Our conductors and cables play a critical role in the efficient transmission and distribution of electrical power, powering homes, businesses, and industries around the globe. With our commitment to quality, and customer satisfaction, BPPL products continue to drive progress worldwide, contributing to the advancement and sustainability of global markets.